As the name is implying a thermal power plant or thermal power station is used to generate the electricity using the heat. The source of heat can be any fuel like coal, gas, oil and urban solid waste etc. energy of coal into electrical energy. The fuel typically coal is burnt in a steam boiler to generate high pressure steam that causes the turbine to revolve hence producing huge mechanical power which drives the alternator coupled to the turbine ultimately producing the thermal electricity. Thermal Power Plants are working on the principle of law of conservation of energy i.e. converting one type of energy into another form i.e. electricity.

Rankine Cycle & Thermal Electricity

The Rankine cycle is a cycle that converts heat into work. The heat is supplied externally to a closed loop, which usually uses water. This cycle generates about 90% of all electric power used throughout the world i.e thermal electricity. William John Macquorn Rankine was a Scottish civil engineer, physicist and mathematician. He was a founding contributor, with Rudolf Clausius and William Thomson, to the science of thermodynamics, particularly focusing on the first of the three thermodynamic laws.

Principle of Thermal Power Electricity

Kinetic energy from high pressure steam converted to rotational energy which rotates the rotor of generator. Blades are designed in a way so as not to strike the blades but to glide on to avoid wearing. Total motive force acting on the blades is thus the resultant of all the centrifugal plus the change of momentum.

Currently most thermal power electricity generation is done using the coal as primary fuel due to its availability and of course it is cheaper than other fuels that can be used in thermal electricity production. Coal cost in terms of usable energy is much less than oil and natural gases i.e. only 12 to 15 % of these fuels. Although handling of coal is difficult and there are serious concerns about its impact on global environment and it green house affect still coal can be a cheaper choice if stringent environmental control technologies are implemented.

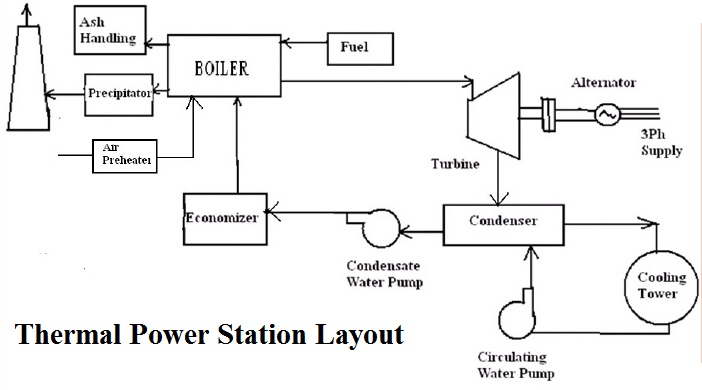

Thermal Power Station Layout

COMPONENTS OF A THERMAL POWER STATION

- COAL HANDLING PLANT: The function of coal handling plant is automatic feeding of coal to the boiler furnace. This should be noted that coal thermal power plant burns enormous amounts of coal which may be estimated for 200MW electricity generating plant around 2000 tons per day.

- PULVERIZING PLANT / COAL MILL: In modern thermal power generation plants in order to achieve maximum burning efficiency coal is pulverized or ground in order to mix it with the hot air and then feeding to furnace in a stream of hot air. This helps increasing the surface area of the coal to action of oxygen and consequently helping combustion. Different types of coal pulverizing mills are used i.e. Contact mill, Ball mill and impact mill etc.

- AIR DRAFT SYSTEM: Fresh air is very important for burning process and circulation of air is caused by a difference in pressure which is termed as Draft. Draft is a differential pressure between atmosphere and inside the steam boiler. It is necessary to cause the flow of gases through boiler setting.

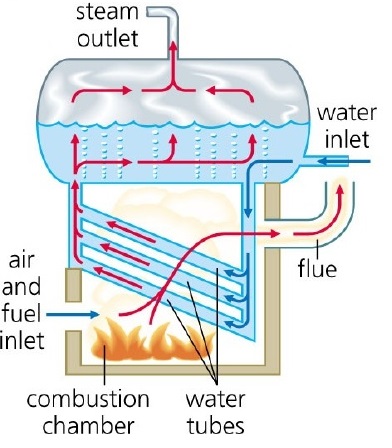

STEAM BOILER

STEAM BOILER - STEAM BOILER: Steam boiler or steam generator which is integral part of any steam power plant is a closed vessel in which water under pressure, is converted into steam. It is one of the major and very critical components of a thermal power plant and it is designed to absorb maximum amount of heat released in the process of combustion. Mostly used steam boilers are Fire tube boiler or Water tube boiler. Most of the modern steam boilers are having super heater and reheater arrangement. Superheater is a component of a steam-generating unit in which steam, after it has left the boiler drum, is heated above its saturation temperature. The amount of superheat added to the steam is influenced by the location, arrangement, and amount of super heater surface installed, as well as the rating of the boiler. The super heater may consist of one or more stages of tube banks arranged to effectively transfer heat from the products of combustion. Super heaters are classified as convection , radiant or combination of these. Some of the heat of super-heated steam is used to rotate the steam turbine where it loses some of its energy. Reheater is also steam boiler component in which heat is added to this intermediate-pressure steam, which has given up some of its energy in expansion through the high-pressure turbine. The steam in a boiler after reheating is used to rotate the second steam turbine where the heat is converted to mechanical energy. This mechanical energy is used to run the alternator, which is coupled to turbine , there by generating electrical energy.

STEAM TURBINE

STEAM TURBINE - STEAM TURBINE: Steam turbine converts heat energy of steam into mechanical energy and drives the electricity generator. So turbine is the component that convert Thermal Power in to kinetic energy. It uses the principle that steam when issuing from a small opening attains a high velocity. This velocity attained during expansion depends on the initial and final heat content of the steam. This difference between initial and final heat content represents the heat energy converted into kinetic energy. Two types of turbines are used impulse turbine and reaction turbine.

- ASH HANDLING PLANT is very important part because plenty of coal ash is generated which is then transported away for other purposes like burning for cement production etc.

- CONDENSER: Steam after rotating steam turbine comes to condenser. Condenser is actually shell and tube heat exchanger that converts steam from its gaseous to its liquid state, also known as phase transition.

- COOLING TOWERS AND WATER PONDS: Water cooling is very important for working of thermal power plant. Condensation process involves huge quantity of water to condense the hot steam. Cooling tower provides cooling to the water which is reused in the power generation process.

- FEED WATER HEATER is used for heating water before feeding back to the boiler which improves overall plant efficiency and dissolved oxygen and carbon dioxide which can cause boiler corrosion are removed in feed water heater.

- Economizer is used to extracts a part of heat from flue gases and uses it for heating feed water. This use of economizer results in saving coal consumption and higher steam boiler efficiency as well.

- Air pre heater: After flue gases leave economizer, some further heat is extracted from them and used to heat incoming air. Roughly cooling of flue gases by 20 degree centigrade increases the plant efficiency by 1%. Air preheaters may be of three types Plate type, tubular type and regenerative type.