You can find below a comprehensive switchgear testing and commissioning procedure. If you need to learn and understand the switchgear testing and commissioning procedure then this article is enough.

But if you want to submit to client/consultant the method statement for switchgear testing and commissioning then you can download full document with ITP, checklists and risk assessment.

Download Method Statement for Testing & Commissioning Of MDB, SMDB, DB, MCC & Capacitor Bank

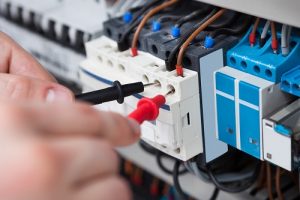

It is necessary that all testing tools are available before starting the work. Therefore at least following tools shall be arranged before starting the electrical testing job.

Most importantly all measuring tools must have valid calibration certificate at the time of switchgear testing and commissioning of switchgear.

All workers to comply the safety requirements such as safety shoes, safety helmet, safety glasses, fluorescent vest, and safety gloves to ensure maximum ability of safe work.

- Portable Electrician Tools

- Insulation Testing Equipment

- Digital Multi-meter

- Measuring Tape

- Ladder / Scaffolding

Pre-Requisites for switchgear testing and commissioning

Obtain the permit to work PTW for starting the electrical testing and commissioning T&C activity. PTW should be signed by all parties with valid dates and times related to the specific activity and equipment.

Physical checking or pre commissioning procedure

Check the cable installation and ensure the following are in accordance with the approved shop drawings.

- Ensure spacing between cables is as per approved drawings and specifications.

- Check cable identification and labeling as per schedules.

- Bending radius is as per manufacturer recommendations

- Make sure that the glanding and gland Earthing complete and approval is available.

- No physical damages to switchgear and all connected cables

Switchgear Testing and Commissioning Procedure

Busbar Torque Test: After installation of the switchboards, all the bus bar bolts are torque tested as per manufacturer’s recommendations by using a calibrated torque wrench.

Breaker to Breaker Resistance Test

Measure Breaker-to-Breaker resistance by connecting a micro-ohm meter between adjacent panels by applying 100A DC for 10 seconds for each phase.

Repeat the above step for the other phases and other breakers as applicable.

Current Transformer CT Testing Procedure

- Insulation Resistance Measurement: Measure insulation resistance of C.T secondary windings using 500V megger.

- Polarity check: The DC voltage test momentarily imposes a small DC voltage on one side of a CT (Primary) and the direction of the momentary deflection of a meter on the opposite side (Secondary) of the CT is noted and compared with polarity marks.

- Winding resistance Test: The secondary winding resistance of the CT is measured using the Ductor for each phase.

- Ratio Test: Applying the current in the primary and by measuring the secondary current do the ratio test. Then dividing the value of the primary current by the secondary current checks the ratio of the CT. (This is to be done for all phases).

- From protection CT verify the saturation point.

Voltage Transformer VT Testing Procedure

Insulation Resistance Measurement:

- Measuring insulation resistance of VT primary to earth by using 5000V Megger.

- Measuring insulation resistance of VT secondary to earth by using 500V Megger.

- Measuring insulation resistance of VT primary to secondary by using 1000V Megger.

Polarity check: The check is made by imposing a small DC voltage on VT (Primary) to the earth and the direction of the momentary deflection of a sensitive voltmeter on the opposite side (Secondary) to the earth of the VT is noted.

Winding resistance Test: The primary and secondary winding resistance of the VT with respect to their neutrals is measured using the Ductor for each phase.

Ratio Test: Applying the three-phase voltage on the primary side and by measuring the secondary voltage for each phase does the ratio test. Then dividing the value of the primary voltage by the secondary voltage checks the ratio of the VT.

Relay Testing

All the relays are to be tested by secondary injection through CT and VT terminals using the secondary injection kit according to the manuals & approved test formats given.

High Voltage Testing Procedure

High voltage test is done by applying 80% of factory-tested voltage. While doing the HV test the steps to be followed are as below:

- Short all CTs circuits.

- Isolate all VTs.

- All the CBs are made into service.

- For doing ‘R’ phase the other phases are shorted and earthed.

- Before HV IR test 5kV megger is to be done.

- HV test as said above done for 1 minute and the leakage current is recorded from the kit.

- After HV IR test 5kV megger is to be done.

The above said is also repeated for other phases also.

Primary Injection Test

Primary injection is done by applying current in primary of the CT and measuring the current up to the last point of the secondary circuit by making all the CT circuits through. This test is proving the secondary circuit of CTs is proper.

Overall Functional Checks & Tests

- Overall functional checking is done according to the approved sequence and drawings. All the interlocks, operations, tripping & alarms are checked that these are working as per the design.

- Injection tests (Primary and Secondary)

- Insulation test

- Partial discharge and ultrasound test

- Infrared thermo-electric detection

- Any other manufacturer recommended test

Discover more from Electrical Engineering 123

Subscribe to get the latest posts to your email.

I believe that an electrical engineer has all the measuring tools needed to test our switchgear. Thanks for saying that we should obtain a permit beforehand to make sure we’re not violating any standards. Once it’s done, we’ll be able to know which parts need to be replaced.